In the realm of air duct system design, air duct fittings equivalent length emerges as a pivotal concept, shaping the overall performance and efficiency of these systems. This comprehensive guide delves into the intricacies of equivalent length, exploring its definition, influencing factors, calculation methods, and impact on duct system design.

By understanding and leveraging equivalent length, engineers can optimize airflow, minimize pressure losses, and ensure the optimal functioning of air duct systems.

1. Definition and Purpose of Air Duct Fittings Equivalent Length

In the design of air duct systems, the concept of equivalent length is crucial for determining pressure drop and airflow resistance. Equivalent length is a measure of the pressure drop caused by a fitting relative to a straight duct of the same diameter.

By understanding equivalent length, engineers can accurately predict the performance of air duct systems and make informed decisions about fitting selection and system layout.

2. Factors Affecting Equivalent Length

The equivalent length of an air duct fitting is influenced by several factors:

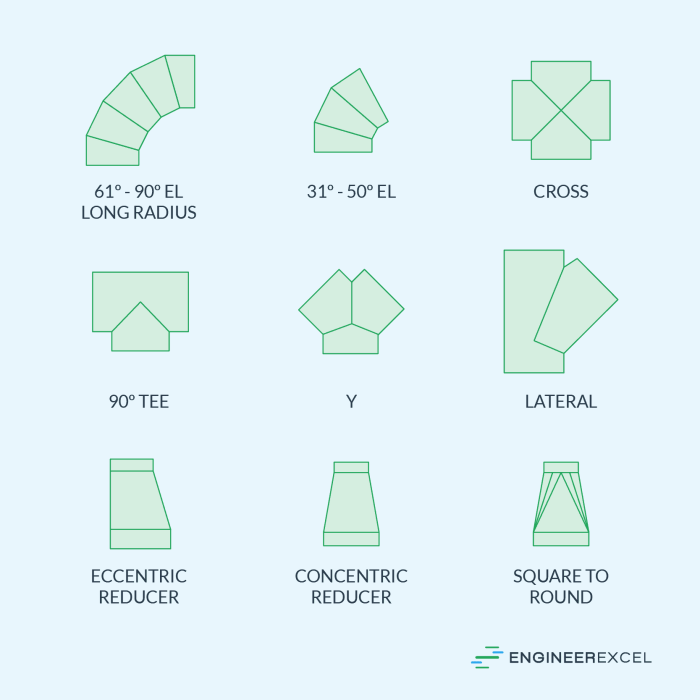

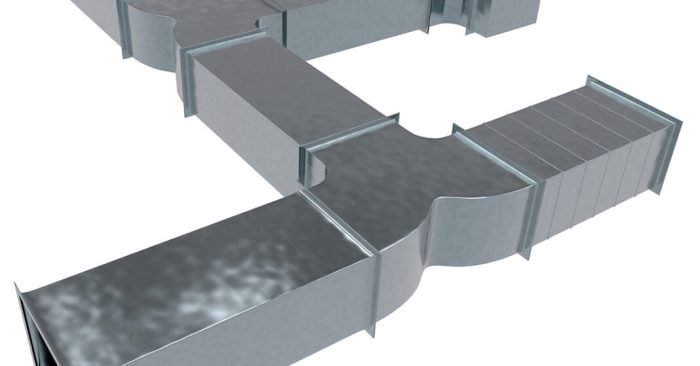

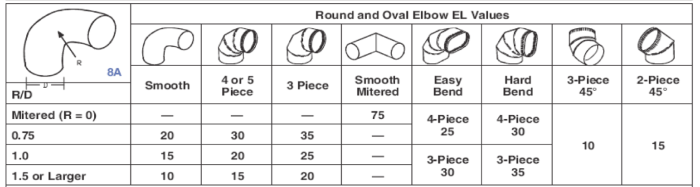

- Fitting geometry:Different fitting shapes and configurations, such as elbows, tees, and reducers, have varying equivalent lengths.

- Fitting size:The size of a fitting, particularly its diameter and cross-sectional area, affects its equivalent length.

- Fitting orientation:The orientation of a fitting, such as the angle of an elbow or the direction of a tee branch, can impact its equivalent length.

3. Methods for Calculating Equivalent Length

Various methods exist for calculating the equivalent length of air duct fittings:

- Experimental methods:Direct measurements of pressure drop through fittings can be used to determine equivalent length.

- Empirical equations:Formulas developed from experimental data can be used to estimate equivalent length based on fitting type and dimensions.

- Computational fluid dynamics (CFD):CFD simulations can be used to model airflow through fittings and calculate equivalent length.

The accuracy and limitations of each method vary, and the choice of method depends on factors such as fitting complexity and available resources.

4. Impact of Equivalent Length on Duct System Design

Equivalent length has a significant impact on the performance of air duct systems:

- Pressure drop:Fittings with high equivalent lengths contribute to increased pressure drop in the system, requiring higher fan power to maintain airflow.

- Airflow resistance:Fittings with high equivalent lengths create resistance to airflow, reducing the overall efficiency of the system.

- System sizing:Equivalent length affects the sizing of ducts and fans, as larger ducts and more powerful fans may be required to compensate for pressure losses caused by fittings.

5. Design Considerations for Minimizing Equivalent Length

To minimize equivalent length in air duct system design, several strategies can be employed:

- Streamlined fittings:Fittings with smooth transitions and reduced turbulence, such as long-radius elbows, can minimize equivalent length.

- Proper fitting placement:Orienting fittings correctly and spacing them appropriately can reduce pressure losses and equivalent length.

- Alternative duct configurations:In some cases, using alternative duct configurations, such as wyes instead of tees, can reduce equivalent length.

Top FAQs: Air Duct Fittings Equivalent Length

What is the significance of equivalent length in air duct system design?

Equivalent length is crucial in determining the pressure drop and airflow resistance within duct systems, allowing engineers to accurately size ducts, select fans, and design system layouts that meet performance requirements.

How can I calculate the equivalent length of air duct fittings?

Various methods exist for calculating equivalent length, including formulas and equations based on fitting type and dimensions. Engineers can choose the most appropriate method based on the specific fittings and system configuration.

What are some strategies for minimizing equivalent length in air duct systems?

To minimize equivalent length, engineers can employ streamlined fittings, optimize fitting placement, and consider alternative duct configurations. These strategies help reduce pressure losses and improve airflow efficiency.